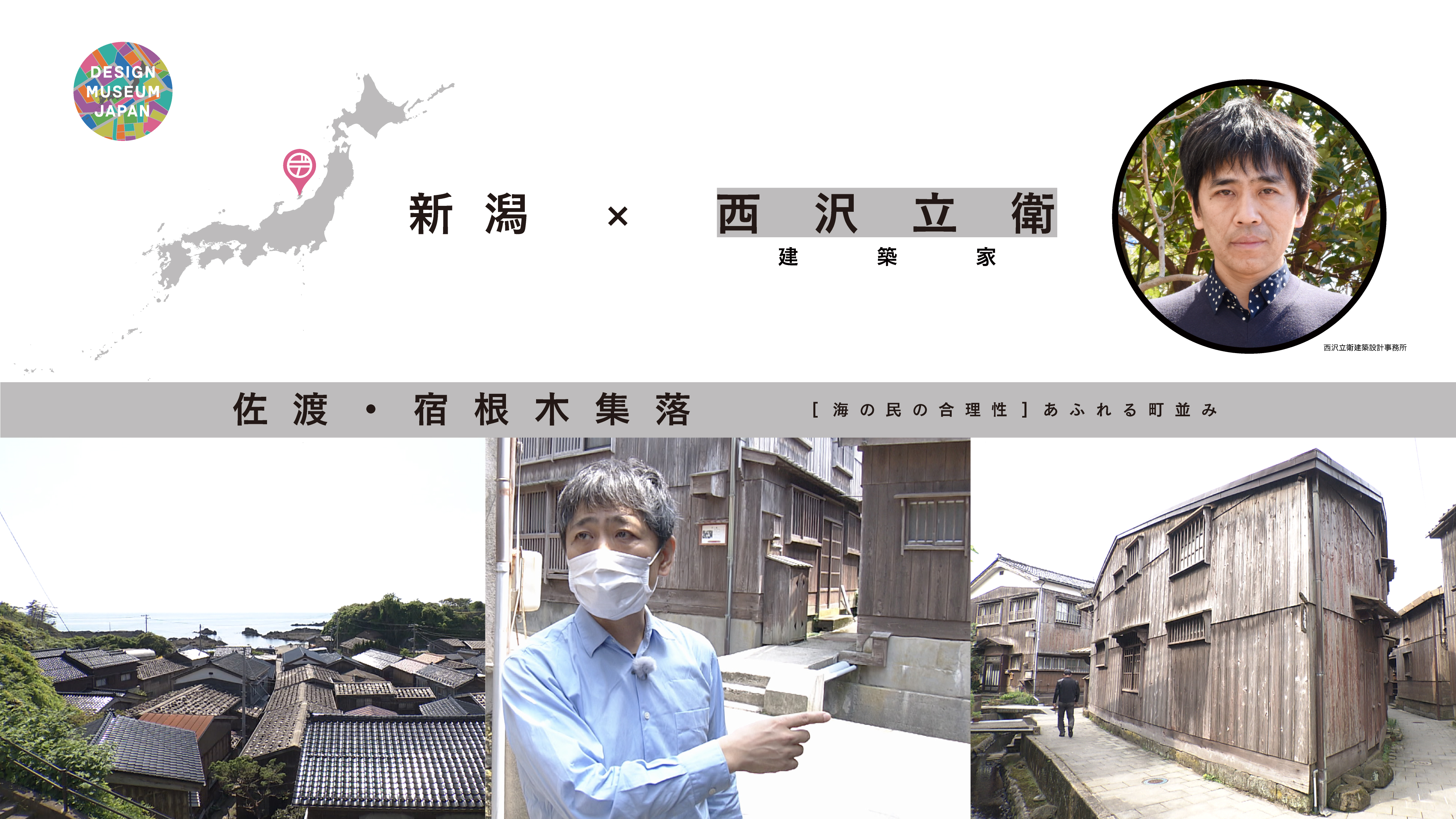

Kenya Hara’s research was conducted in his hometown in Okayama prefecture. He visited a manufacturer of screw propellers, which boasts the biggest market share in the world. The factory in Tamashima is located close to the busy shipping lanes of the Seto Inland Sea. The site is perfect not only for serving nearby shipping companies but also for sending finished propellers to customers in distant places. The company started out in 1926 mostly with propellers for fishing boats and moved into large propellers, too, from 1952. The propellers are made by combining traditional craftsmanship with the latest technologies, and support the global flow of goods.

Kenya Hara Graphic Designer

Propellers

DESIGN TREASURE

Perfect Forms that Produce Efficiency

CREATOR

Kenya Hara Graphic Designer

Born in Okayama in 1958.

Hara’s main field is graphic design but he also reaches out through museum curation, writings etc. to describe the latent power of design and visualize its unseen capability. His Re Design: Daily Products of the 21st Century exhibition has toured globally and he is known for tackling conventional values through key words such as “haptic”, “senseware” and “ex-formation”. His activities extend across the extremely broad range from art direction for Ryohin Keikaku (Muji) to visual identity (VI) projects for Matsuya Ginza, Mori Building, Tsutaya Books, Ginza Six, Mikimoto and Yamato Transport.

Screw propeller model

Courtesy of Intermediatheque, The University Museum, University of Tokyo

Propeller shape−there is no margin

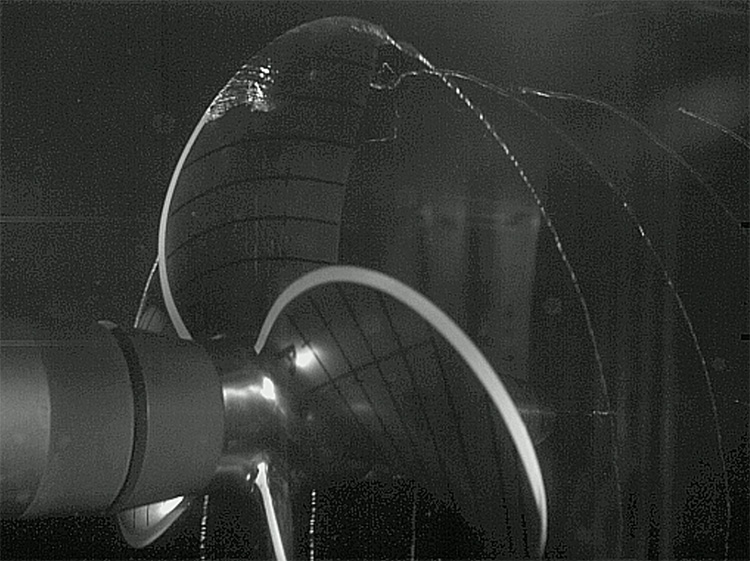

The idea for the screw propeller was born in Ancient Greece but the quest for ever greater horsepower and speed really dates back to the Industrial Revolution in the 19th century. The screw principle is harnessed to produce the thrust that propels the vessel forward. Long helical screws were tried at first but short blades proved more effective for propulsion through water and gave rise over time to the modern propeller shapes. The form and number of the blades depends on the size of the boat and speed requirements. Efficiency is maximized through application of the most suitable manufacturing processes. Propeller is “a form with a clear basis.” remarked Hara.

Screw propeller model

Courtesy of Intermediatheque, The University Museum, University of Tokyo

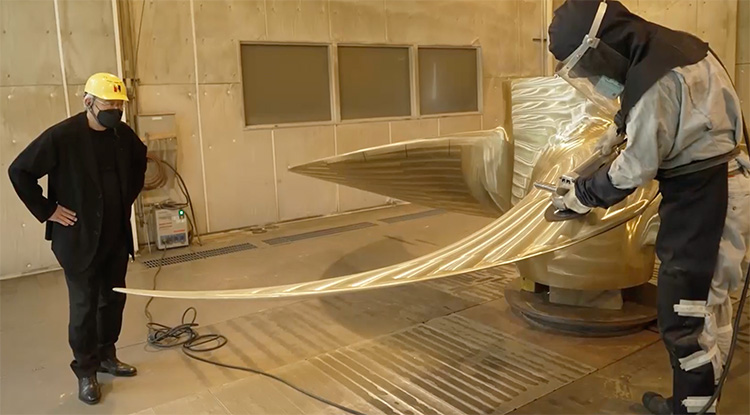

Propeller being stamped out of mold

Hara is impressed by the huge propeller in front of him.

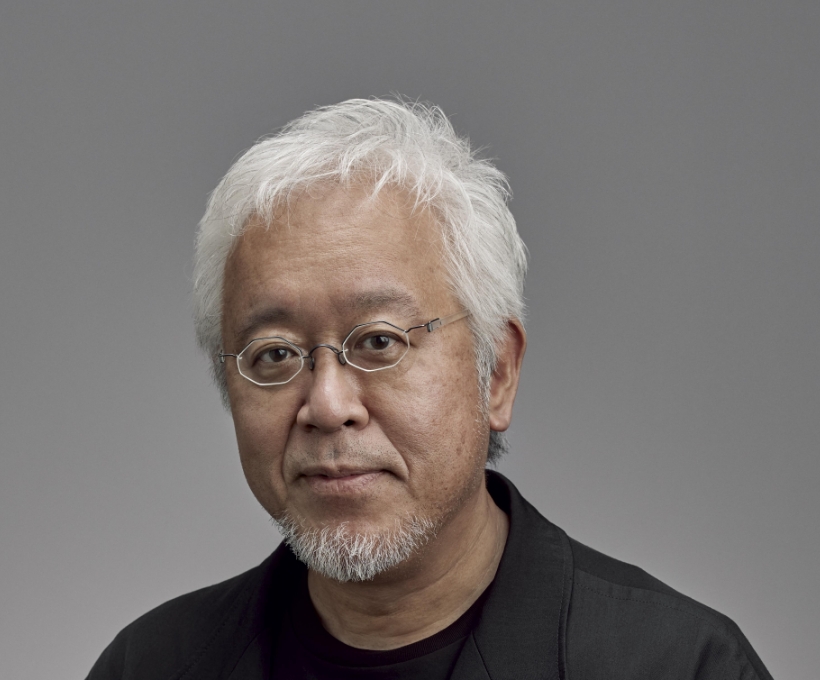

The craft sense which produces functional perfection

Hara is overwhelmed by the screw propeller for large vessels, which has a diameter of 8.2 meters. He is impressed not only by its size but also by the attention to detail. The wing part is first cast in a mold and polished by machine, and the surface then finished by hand to 0.01mm precision. Air bubbles generated when the propeller rotates affect the ship's propulsion, vibration, and energy consumption. To reduce the generation of these bubbles, the resistance due to the uneven surface of the blades is precisely calculated. “I was surprised to learn that the work that makes something so enormous precise is done by the human hand,” remarked Hara. For him, the perfection of form embodies the essence of craft beauty.

Technician polishing a propeller

Smoothly curved propeller surface

The surface of the propeller is fine-tuned to the nearest 1/100th of a millimeter by hand by technician.

Beauty that resides where no-one will see it

Propeller is submerged while the ship is in motion, so such parts are rarely seen. It is an object that was made for a purely mechanical purpose: To transform rotational force into propulsion. However, its shape is infinitely beautiful,” he remarks getting emotional. “It is not about individual expression, rather about an unshakable form without any unnecessary element that keeps pace with rationality and the laws of nature,” he adds.

Propeller spinning underwater

Propeller installed on a giant ship

To reduce the amount of bubbles generated during rotation, even the resistance of the surface of the blades is precisely calculated.

Where Can We See This Design Treasure?

Installation view: Okayama Prefecture, Kurashiki City by Kenya Hara, DESIGN MUSEUM JAPAN Exhibition at The National Art Center, Tokyo, Japan, 2022