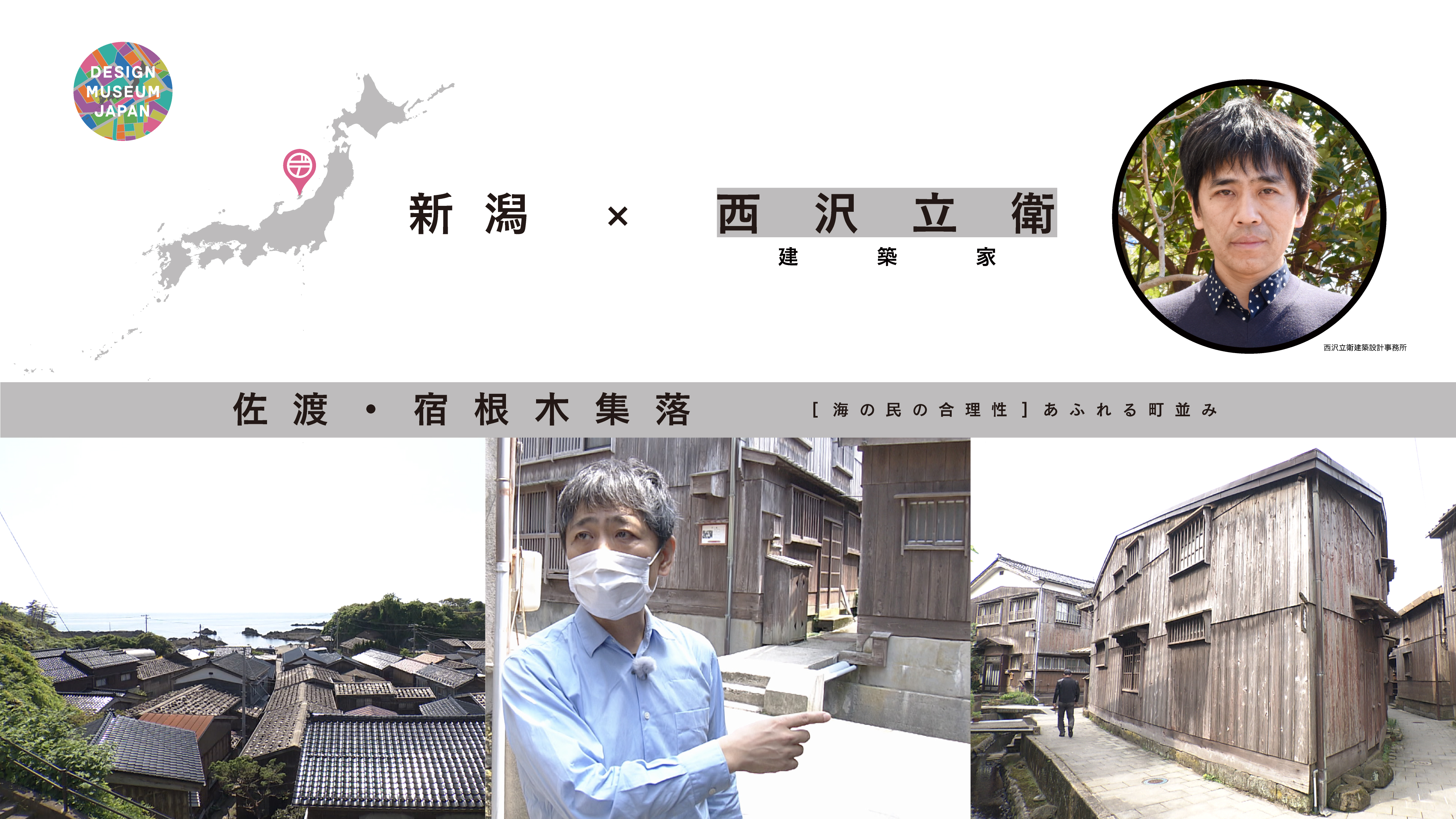

In his research, Akira Minagawa visited the factory of “Yamagata Dantsu,” a wool carpet produced in Yamagata. The Yamagata Dantsu is made in the small town of Yamanobe in Yamagata Prefecture, Other famous Dantsu carpets, each with its own long history, include the Dantsu of Nabeshima in Saga and Sakai in Osaka. The Yamagata Dantsu, by contrast, dates only from the first half of the 20th century. Production started in 1935. The trigger was a recession brought by cold-weather damage to crops in the Tohoku region. People were looking for a new industry to improve their lives, and carpet makers from China were invited over to teach them the techniques. A degree of mechanization that combined both machine and hand work was introduced from 1965, but the old hand-weaving production has been also continued.

Akira Minagawa Designer

Yamagata Dantsu Carpets

DESIGN TREASURE

Designs that underpin everyday life in the snow country

Producing a hand-woven Dantsu carpet

Photo courtesy of Oriental Carpet Mills, Ltd..

CREATOR

Photo by Shoji Onuma

Akira Minagawa Designer

Born in Tokyo in 1967,

Minagawa founded Minä, the forerunner of Minä Perhonen, in 1995. Chiefly engaging in textile design using patterns mostly drawn by hand, Minagawa works in a wide range of everyday lifestyle design. He designed the uniforms for the Aomori Museum of Art and 21st Century Museum of Contemporary Art, Kanazawa. He has provided designs for the Kvadrat and Klippan textile brands in Denmark and Sweden, respectively, and the Ginori 1735 porcelain brand in Italy, and also illustrates for newspapers and magazines.

Minagawa watching hand-weaving of Dantsucarpet.

Dantsu after cleaning

A mode that suits the Japanese lifestyle and the value of making things by hand

Minagawa was surprised at the softness of Yamagata Dantsu, saying, “The Dantsu carpet is very comfortable and a good fit with the Japanese lifestyle, whether walking barefoot or lounging on the floor.” The secret of the unique texture lies in the process. The process begins with the preparation of wool yarn, which is the raw material, and then moves on to dyeing and weaving. Weave one step and use a special tool to adjust the density. The same processes are repeated thousands of times a day. After weaving surface finishing and embossing according to the design are then followed by separation of the threads by scissors and tweezers and cutting off loose threads. The meticulous handicraft attention to detail is maintained to the last. “I believe this kind of work nurtures both functional richness and the sense of gratitude,” Minagawa pays tribute.

Minagawa checks the feeling of touch

Wool yarn as material

Courtesy of Oriental Carpet Mills, Ltd..

Yarn dyeing

Courtesy of Oriental Carpet Mills, Ltd..

Finishing

Courtesy of Oriental Carpet Mills, Ltd..

The passion to make and explore−Kudzu root carpets

In the difficult post-war years when wool was hard to obtain, the carpet weavers hit on the use of thread made from the root of the kudzu vine. The original carpet maker recalled: “On days when the snow was falling, craftsmen’ hands became numb and blistered from digging up the kudzu roots and spinning the thread, but small flannel-sized mats were made.” The times were hard but a way, almost a prayer, was found to carry on making carpets. “The kudzu root carpets emerged at a time when raw materials and skills were lacking, the achievement says much about the people’s passion to make and explore.” remarks Minagawa, who adds that “I think that without that kind of passion, the later technological developments and creativity would not have happened, either.”

Kudzu root and three varieties of kudzu root thread

Courtesy of Oriental Carpet Mills, Ltd..

Permeation with the accumulated memories of people’s lives

Some Yamagata Dantsu are produced by the hand-tufting method using a tool called a hook gun. Hand tufting is more efficient than hand-weaving but still mostly involves a lot of labor. After the thread is planted in the base fabric with the hook gun needle, precise cutting and arranging is still needed after tufting, and this has to be done by hand. The technique depends on the mature skill of the artisan. This time, Minagawa designed a new rug using the hand-tufting method. Dantsu carpets are usually made on the principle of evenness and consistency. For Minagawa’s proposal, by contrast, the Kasuri dyeing process was adopted. “Non-homogeneity is a feature of the most relaxing living spaces,” he explains.

Minagawa's design drawing and a prototype of kasuri dyeing

Where Can We See This Design Treasure?

Installation view: Yamagata Prefecture, Yamagata City by Akira Minagawa, DESIGN MUSEUM JAPAN Exhibition at The National Art Center, Tokyo, Japan, 2022

Yamagata Dantsu

Workshop/Showroom

Experience Space

Oriental Carpet Mills, Ltd.

21, Yamanobe, Higashimurayama-gun, Yamagata 990-0301

Click here for more details.