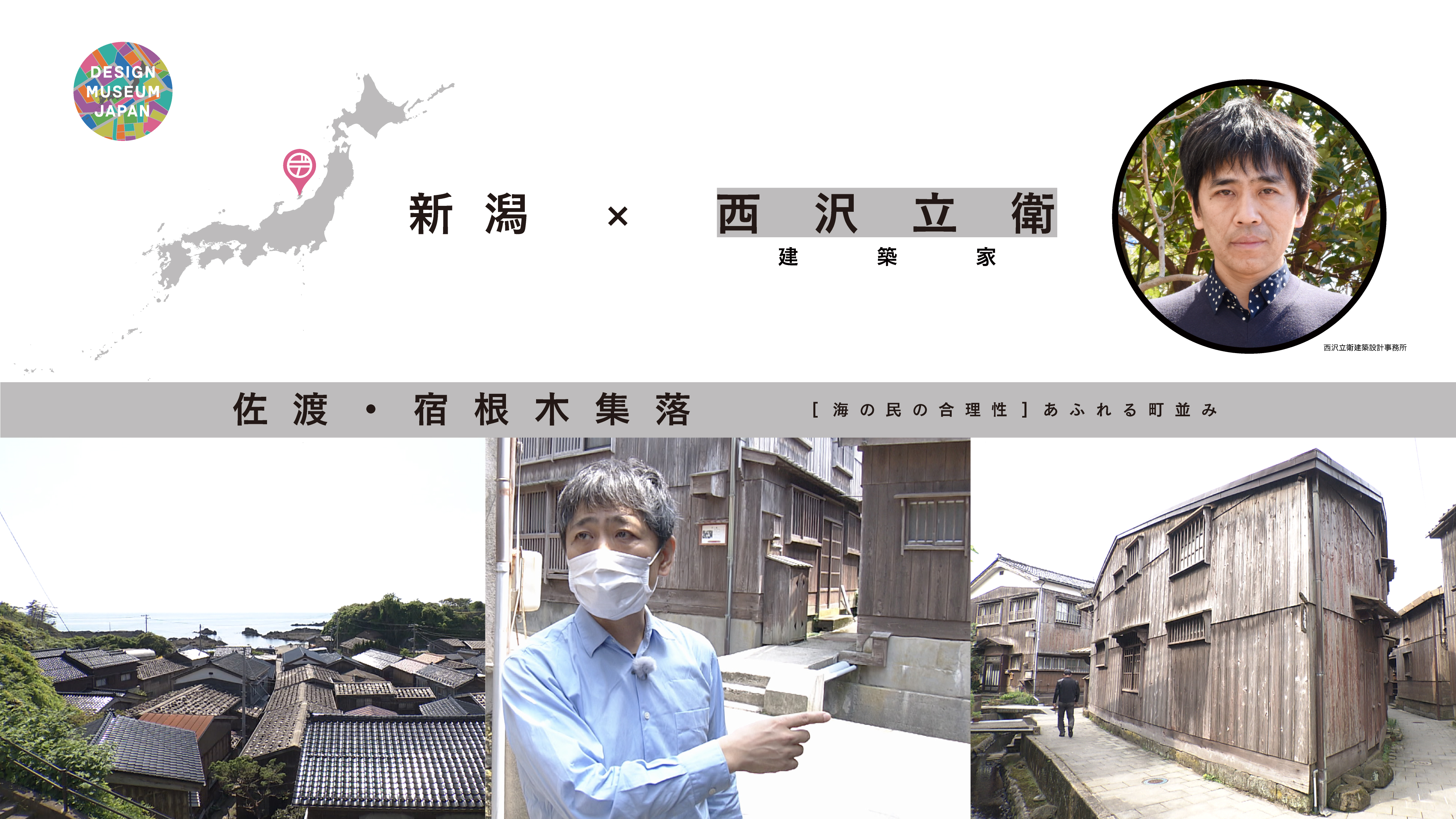

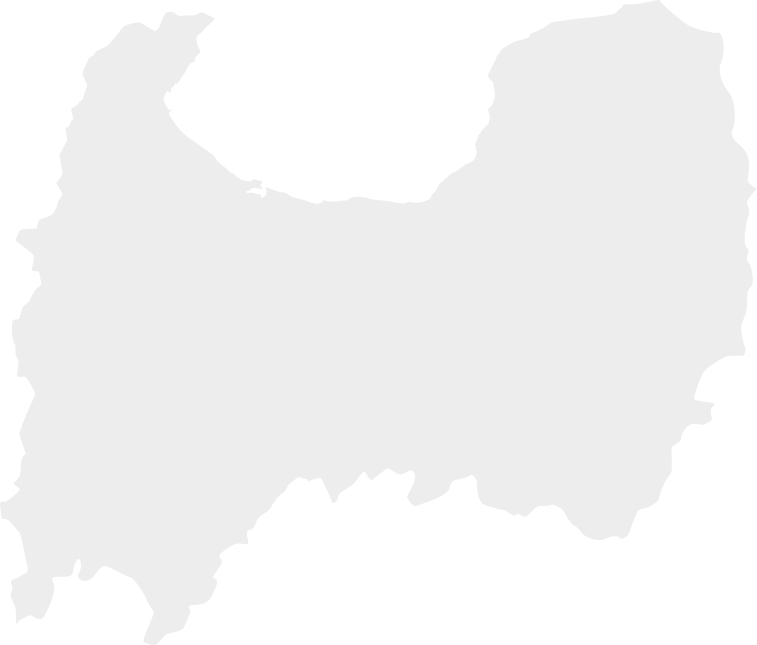

Reiko Sudo researched cutting-edge uniform development at a world-class sportswear manufacturer in Toyama, Hokuriku, where the textile industry is thriving. Shi visited the Meriyasu Seizosho (Knit Fabric Manufacturer) which launched sportswear production using machine woven knits in the Oyabe district of Toyama soon after WWⅡ in 1951 and became a specialty sportswear maker the following year. In the 1960s, the company made the sportswear for the Japan women's volleyball team at the 1964 Tokyo Olympics Games, and also used its knit techniques to expand in ski sweater. The same spirit of challenge still marks the company today as it continues to produce one technical innovation after another.

Reiko Sudo Textile Designer

3D Sportswear

DESIGN TREASURE

Inspired by Toyama’s Andon Lantern Festival

Andon at The Tsuzawa Yotaka Andon Lantern Festival

Sportswear for the “Oriental Witches”

Collection of Goldwin Inc.

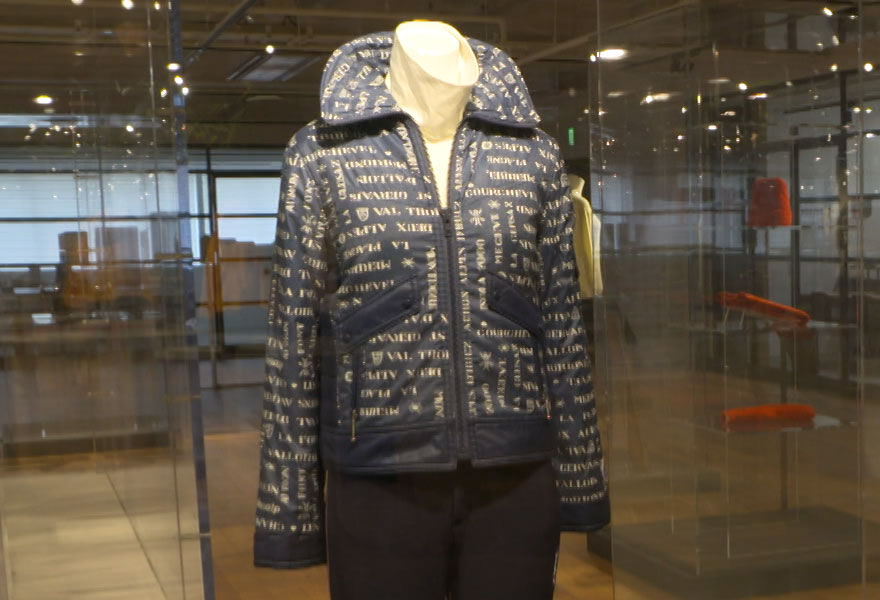

1960’s skiwear

Collection of Goldwin Inc.

CREATOR

Photo by Masayuki Hayashi

Reiko Sudo Textile Designer

Born in Ibaraki.

Sudo creates new textiles using traditional Japanese dyeing and weaving techniques as well as cutting-edge modern technology. She values the endeavor to create textiles that are not easily consumed, but that move people. Sudo has worked as a textile design consultant for Ryohin Keikaku (Muji), the Tsuruoka Fabric Industry Cooperative in Yamagata Prefecture, AZU Corporation and others.

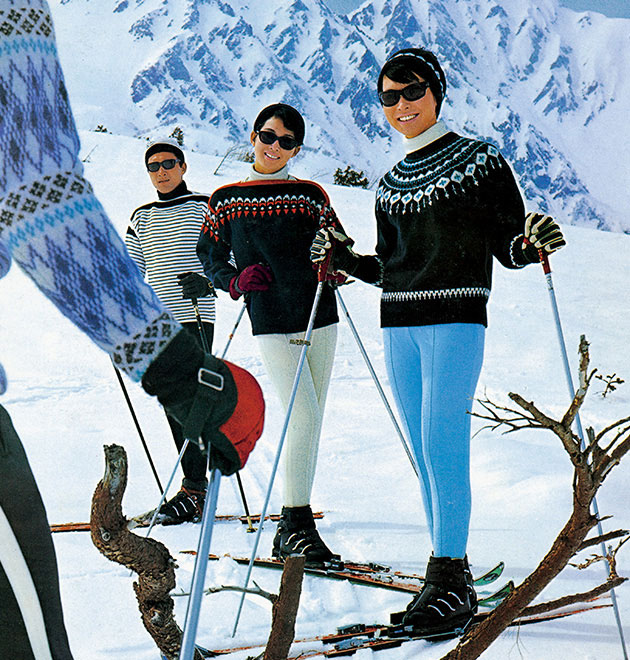

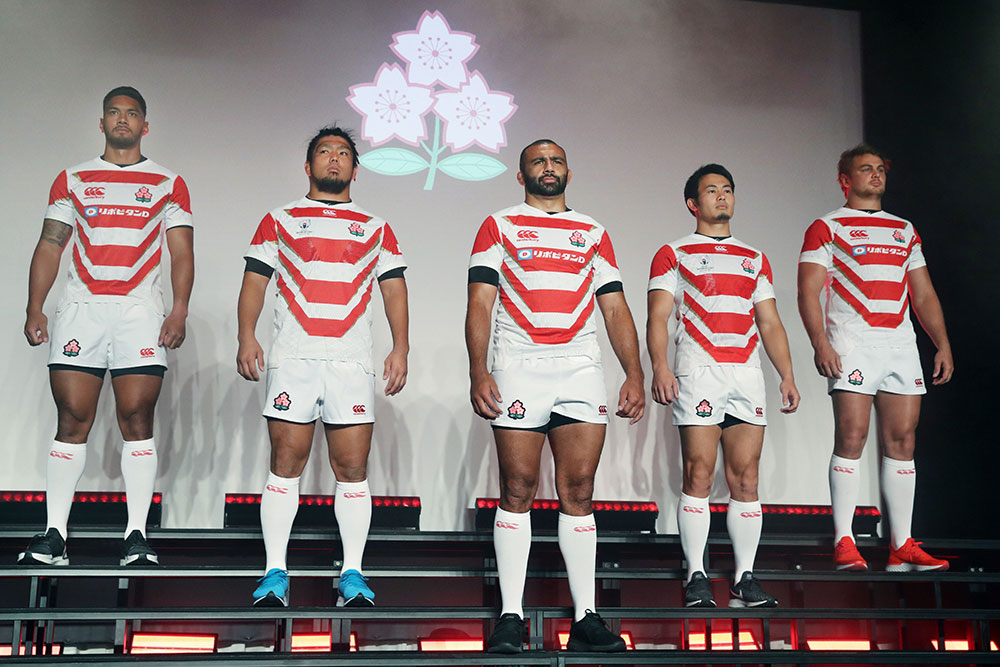

2019 Rugby World Cup Jersey

The haute couture approach to sportswear

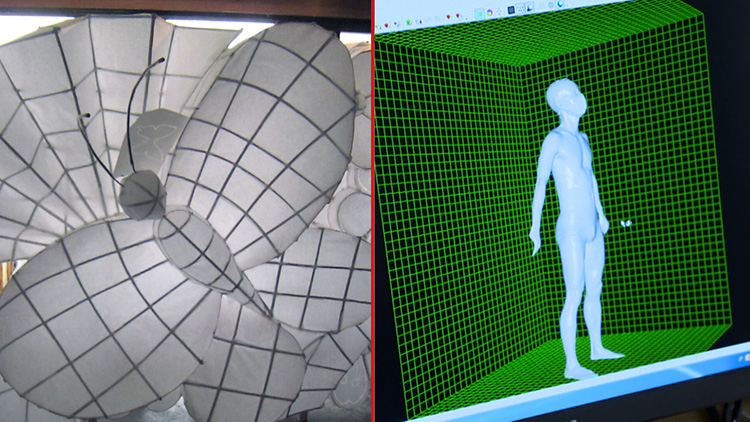

Japan’s first 3D skiwear fabricated for both warmth and competition was made in the 1970’s. Japan’s traditional clothing culture was firmly rooted in 2D development and the challenge of producing Western-style 3D garments wasn’t easy. This was still before the age of computer aided design. The inspiration was found in the traditional Andon Lantern Festival of Oyabe City. The original creator’s childhood experience of making the bamboo frames which turned the 2D drawings into 3D lanterns. This experience nurtured the practice of thinking in 3D and gave birth to “creating clothes that fit every person” including 3D skiwear. “We need clothing that conforms to individual roles, not just decorative ones,” remarked Sudo.

Ski wear manufactured in the 1970s

Collection of Goldwin Inc.

3D scan to measure the body shape in three dimensions and framework of the Andon

Engineer telling a story about when he developed 3D skiwear.

Sportswear that made players feel protected

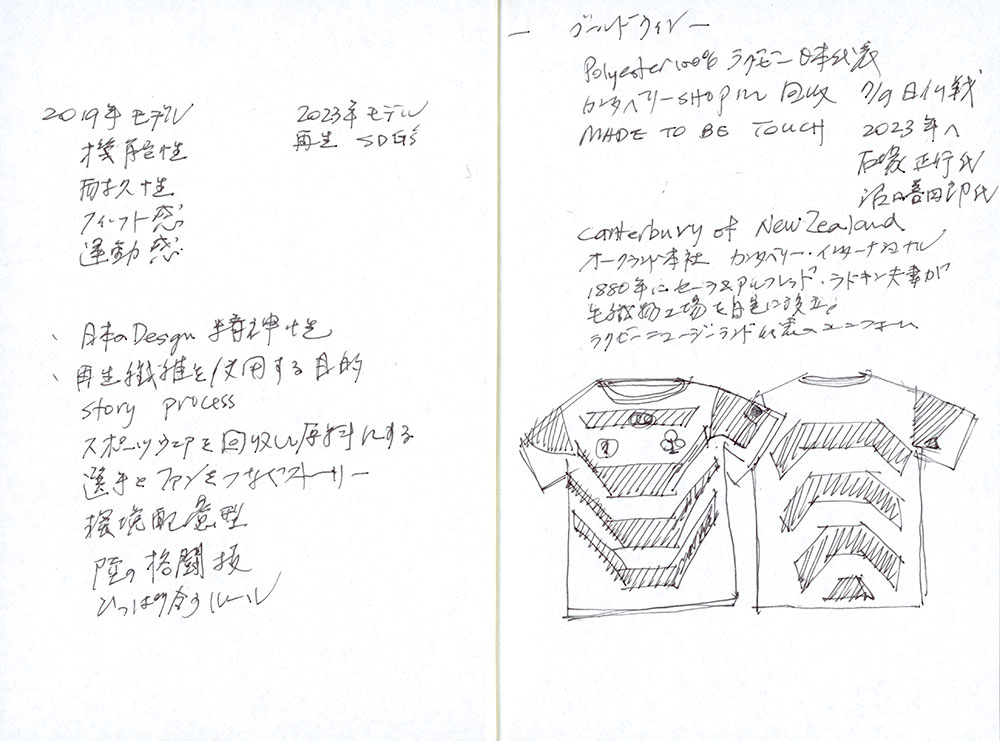

Japan hosted the Rugby World Cup in 2019, that year the Japan team advanced to the quarterfinals for the first time ever. The jerseys worn by the national team have played a large role in Japan’s rising success. It incorporates the latest technology of 3D molding, in which the fabric itself is formed three-dimensionally using heat. They fit the body exactly, were tear resistant, dry quickly, and were also extremely light. The fabric is shaped along the bone, like a skin membrane. It also resembles the washi paper used in the paper lanterns. This jersey as a wear that “becomes part of one’s body” describes Sudo.

Reiko Sudo’s research memos

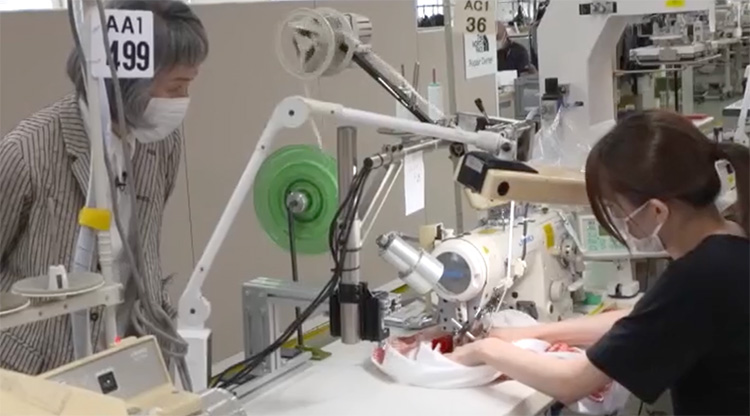

Three-dimensionally formed fabrics

Each garment is crafted beautifully by the artisanal hand.

Design gives power to the users.

The Japan team’s new jerseys were made in three versions according to the playing position: “front row,” “second row/back row,” and “backs.” The fabric is heated and shaped by a special machine, and then sewn into a wear. The concept of haute couture, “creating clothes that fit every person,” is carried through.

The white of the rugby jerseys isn’t just white. The fabric bears traditional symbols of old Japan such as arrow feather (yabane), hemp leaves (asanoha), ocean waves (seikaiha). The players carry the traditions with them. This too, is design.

The Japan Rugby Cup team players in their jerseys

Courtesy of Asahi Shimbun/Uniphoto Press

Where Can We See This Design Treasure?

Installation view: Toyama Prefecture, Oyabe City by Reiko Sudo, DESIGN MUSEUM JAPAN Exhibition at The National Art Center, Tokyo, Japan, 2022

Tsuzawa Yotaka Andon Festival

The evenings of the first Friday and Saturday of June each year

Click here for more details.

GOLDWIN TECH LAB

210 Kiyosawa, Oyabe-city, Toyama 932-0112

Click here for more details.