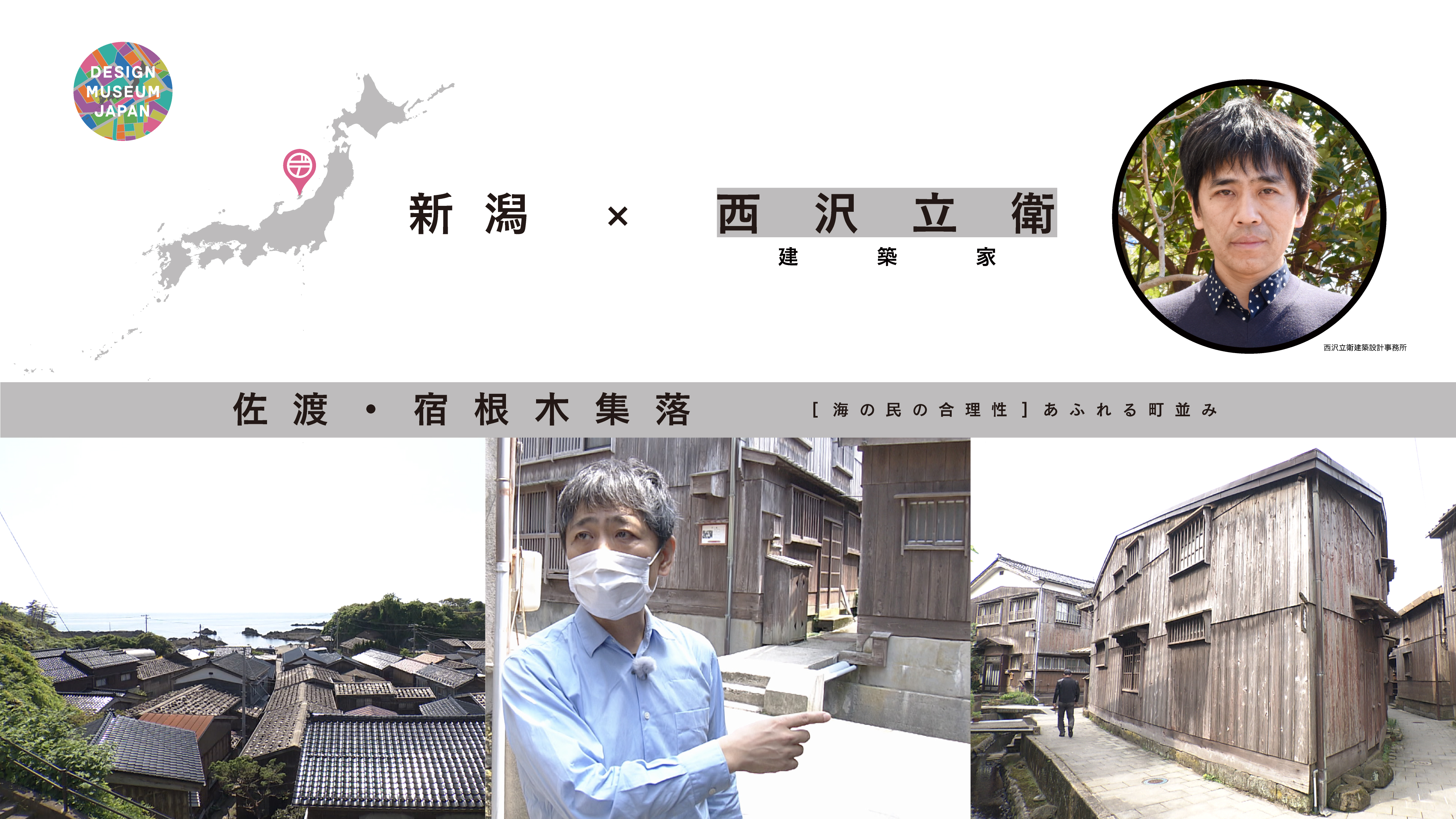

The first vacuum flasks were commercialized in early 20th century Europe and imported to Japan around 1910. Japan’s first domestically produced flasks followed in 1912 when a skilled worker at an electric bulb company, Yagi Teijiro, applied the bulb-making techniques to the task. Osaka was already a city of glassmakers and the number of producers quickly increased to turn the city into a giant of vacuum flask production as well. Igarashi visits the manufacturer now commanding the overwhelming market share for “magic bottles” not only in Japan but worldwide.

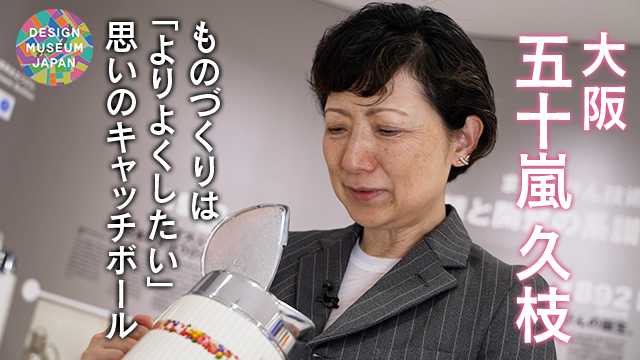

Hisae Igarashi Interior designer

Magic Bottles

Igarashi Hisae researches the vacuum flasks and kettles - called “magic bottles” in Japanese - of the Tenma district of Osaka. Osaka was known as a great glass producing area from the Edo period. It all began with a Nagasaki merchant, Hariyama Seibee, who learned glassmaking techniques from the Dutch and then opened his own glass workshop in Tenma.

DESIGN TREASURE

Special products born from the passion of glassmakers

Glassblowing the inner flasks of the “magic bottles”. Extremely high skill was required.

Photo: Zojirushi Corporation

CREATOR

Igarashi Hisae Interior designer

Born in Tokyo

Igarashi started out at the Kuramata Design Office before establishing her own Igarashi Design Studio in 1993. A proponent of progressive design, she is active across the broad range of clothing, food, home, work and education projects from spatial design for shopping centers and kindergartens to 3D design for furniture, toys and other commercial products. She is a jury member the Good Design and Kids Design awards and professor of the Musashino Art University Department of Scenography, Display and Fashion Design.

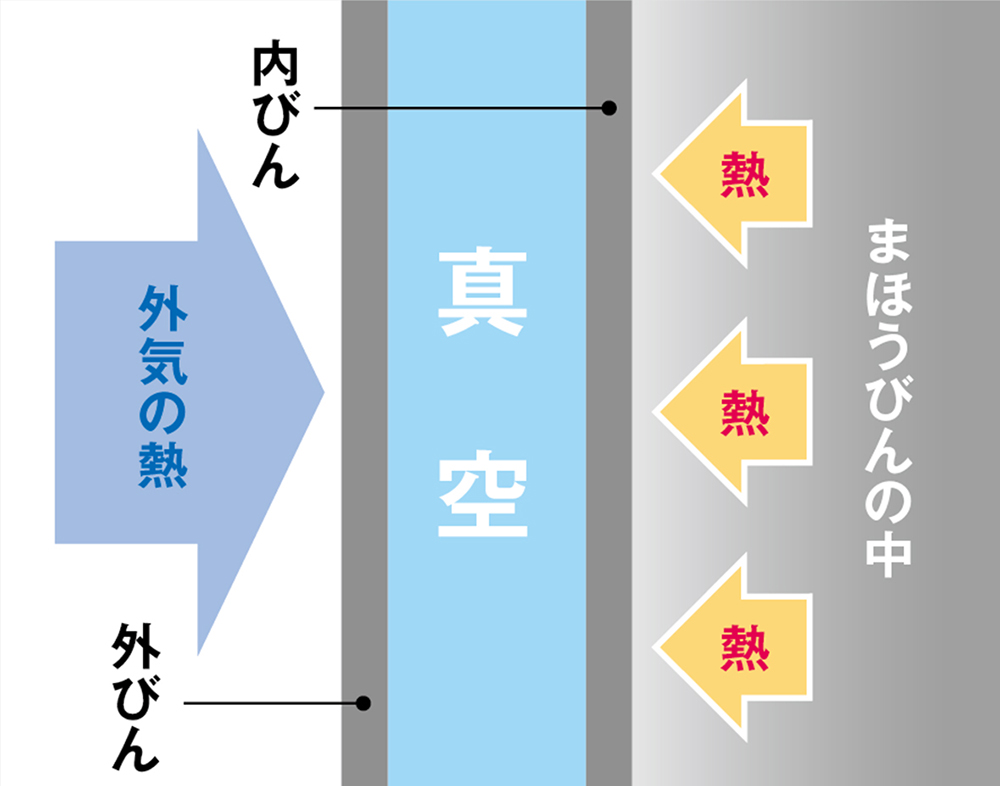

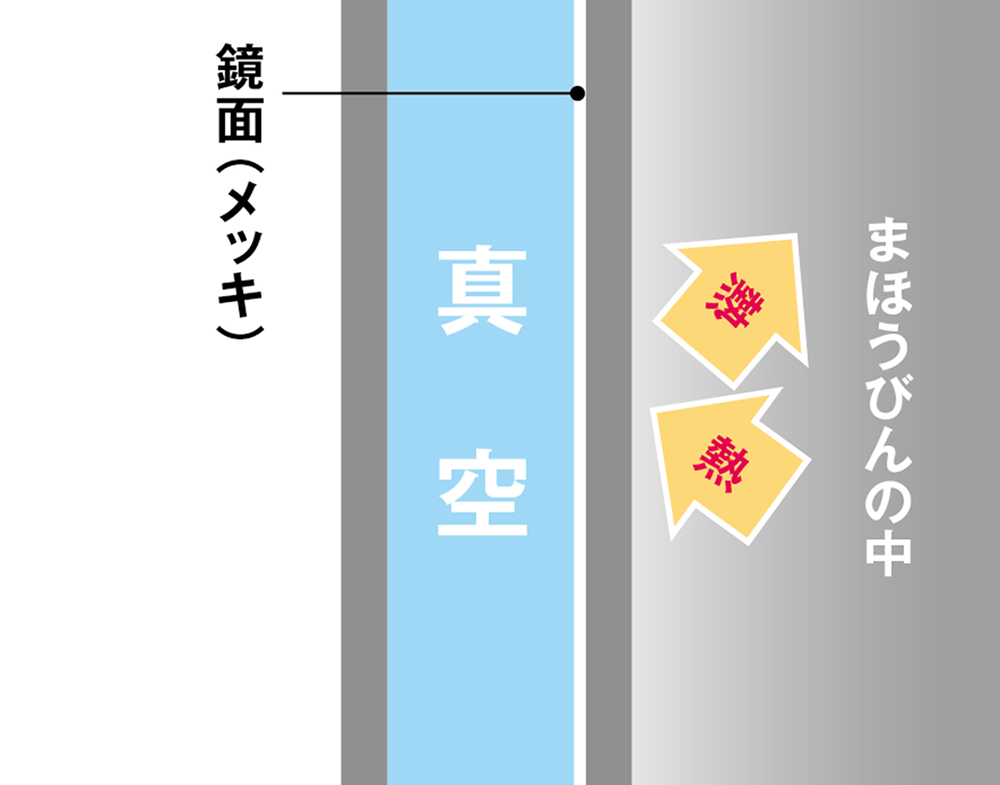

The keys are the two-flask structure and metal plating

The vacuum flask’s outstanding hot and cold temperature retention property is due to the two-flask structure of outer and inner flasks. The vacuum separating the two flasks provides the essential insulation. The same basic structure remains unchanged in today’s stainless steel flasks. Looking inside the glass flask, the vacuum side of the inner flask is metal-plated, turning it into a mirror. This plating holds the radiant heat* in by reflecting it back into the inner flask for even better temperature retention. The combination of glass and metal plating also produces the flask’s distinctive sheen.

*Heat transmitted like rays of light

Some diverse shapes of the inner flasks

The vacuum flask structure. The vacuum is a wall.

Image: Zojirushi Corporation

The vacuum flask structure. The inner wall is a mirror.

Image: Zojirushi Corporation

A sense of nostalgia

We don’t see so many glass vacuum flasks today but they were still the norm in Igarashi’s childhood. The sight reminds her of when she used to help serving tea as a girl. Looking inside, the sheen pulls her into a magical world. “It brings back the old shimmer and sparkle,” says Igarashi. “I even remember the size of the mouth.”

Igarashi looks inside the “magic bottle”.

The mirror-like silver plating is so beautiful.

Shapes that change with the needs of the times

Igarashi is fascinated by the range of vacuum flasks dating from the early 20th century through contemporary times. Each is a vacuum flask, but the designs differ according to the needs and fashions of the day. Metal for the outer flasks was in short supply during the war years and ceramic flasks were used instead. During the rapid economic growth of the post-war period, the fashion was for pots with floral designs that brightened up the kitchen. One weakness of glass flasks was that they were easily broken. That problem was solved by the development of stainless flasks in Japan in 1978. “They weren’t giant leaps,” says Igarashi, “but I find it impressive how this essential everyday product evolved over time to become the flasks we use today.” Ever more people now carry a flask around with them in their bag and lightness and compactness have become the key design features of today.

Igarashi examines flasks of the past

A thin-necked flask from the Taisho Period (early 20th century)

A ceramic outer flask from the wartime years

A post-war “Pot Pelican”

A floral pot from around 1970

Photos: Zojirushi Corporation

The diffusion of glass “magic bottles” abroad

70% of the glass thermos products made by this company are currently exported. Glass that resists impregnation by fragrance is used for the biggest market, the Middle East, where drinks spiced with cardamom and other pungent flavors are popular. The absence of chemical reactions with metal also protects the flavors. The Japanese products have long been admired for their good temperature retention and durability. The increase of inbound tourism to Japan is also raising awareness of Japan’s “magic bottles” overseas.

A stylish contemporary export model

Photo: Zojirushi Corporation

Where Can We See This Design Treasure?

Vacuum Flask Museum (Mahobin Kinenkan)

Besides a permanent exhibition of how thermos flasks have evolved, the museum also presents short-term special exhibitions.

Zojirushi Corporation Headquarters 1F

Address: 1-20-5 Tenma, Kita-ku, Osaka City 530-8511

Please see the website for visiting details.